In the dynamic world of custom men's fashion streetwear, the creation of logos is a critical aspect that embodies both brand identity and aesthetic appeal. This process involves a blend of artistry, precision, and innovative techniques to ensure that each logo stands out and resonates with the target audience.

01

DTG Print

Similar to the principle of a printer, there is no need to make plates, and the pattern is directly printed on the fabric through the principle of CMYK four-color printing, which is suitable for photo effects, gradients or patterns with many details. With breathable and good feeling,It can penetrate into the fabric, more suitable for complex patterns and colors.

02

Heat Transfer Print

Heat transfer print also knowed as hot pressing process,the pattern is printed on hot paper, and then the pattern is transferred to the fabric by high temperature. Hot print pattern is not limited by the number of colors, you can print a photo or gradient effect of the pattern. It is characterized by heavy glue, and is not suitable for large area patterns.

03

Screen Print

Screen print is suitable for solid color patterns with distinct colors, and a set of colors needs to do a set of screen plates, which are manually printed by workers (a large number of machines will be used) using special dyes to print 3-4 times to ensure that the printing will not fall off easily. It is widely used, with bright color and high reduction, suitable for printing of various colors and fabrics

04

Puff Print

Puff Print also known as 3D print, the production method is to brush a layer of foam paste first, and then dry to achieve the pattern foaming, showing the 3D effect of floating sense. It is suitable for solid color patterns with more distinct colors, not for complex patterns with too much details.

05

Reflective print

Reflective print is to add a special reflective material glass beads in the ink, printed on the surface of the fabric, the glass beads on the fabric refraction of the light, so that the incident light back to the direction of the light source. The effect is divided into reflective silver and reflective colorful two effects, the daily look is silver gray, in the light of the light is silver and colorful effect, suitable for the fashion brand pattern

06

Silicon Print

Silicone print uses a special liquid silicone that can be firmly adhered to the surface of the textile by printing on the fabric surface through a silk screen. In addition, there is a silicone engraving film process, the use of engraving equipment, in the silicone transfer film engraved the required graphic text, remove the excess transfer film, leaving the required printing, in the press press, the silicone printing precision hot press onto the fabric

07

3D Embossing

3D Embossing uses a pair of pattern molds with a certain depth to press and roll the fabric at a certain temperature, so that the fabric produces a bump pattern with an embossed effect. Using this process, the garment visually presents a 3D three-dimensional relief effect while maintaining a solid color.

08

Rhinestones

Add rhinestone process is composed of rhinestones and hot drawing, hot drawing is a specific pattern of rhinestone is glued to the back adhesive paper, with the press in the cloth material production. The working principle is that hot drilling meets high temperature,the common temperature is about 150-200, so that the rubber layer at the bottom of the drill melts, thus sticking to the object.

09

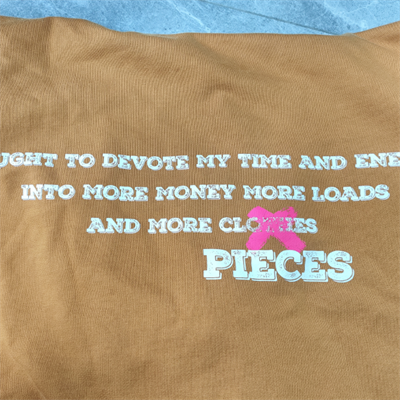

Embroidery

Embroidery is use stitch, swing needle, trocar needle, needle and other different stitches ways to embroidered the logo on the clothes, it is suitable for some simple fonts and logo patterns, it can make the logo in the relatively clean flat fabric to add a certain sense of quality.

10

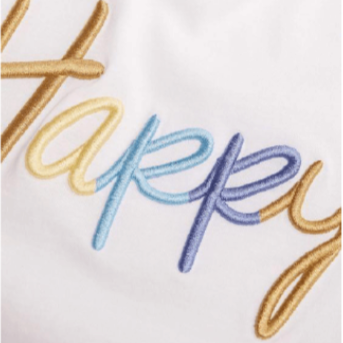

3D embroidery

3D embroidery is also called Bao stem embroidery, that is, embroidery with three-dimensional effect. Use embroidery thread to wrap EVA glue inside to form a three-dimensional effect pattern. Three-dimensional embroidery is more obvious in the visual three-dimensional effect, so as to form a sense of visual layer between the fabric itself or other processes.

11

Chenille embroidery

Chenille embroidery is also called towel embroidery, the effect is very similar to towel fabric. The surface texture is clear, the feel is super soft, the personality is novel and firm, and it is not easy to fall off. It has a certain visual thickness. In recent years, it is suitable for men and women's T-shirts and hoodies.

12

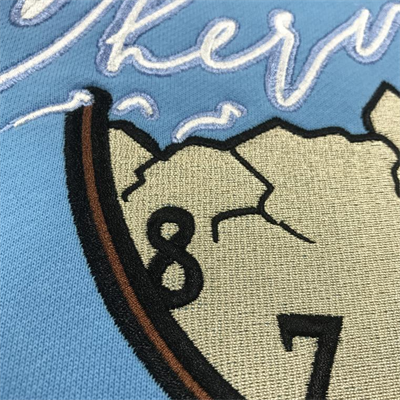

Applique embroidery

Applique embroidery, also known as patchwork embroidery, is to attach another kind of fabric embroidery to the fabric to increase the 3D or split-layer effect. The embroidery method is to cut the patterned cloth according to the pattern requirements and paste it on the embroidered surface, and it can also be padded with cotton and other things between the patterned cloth and the embroidered surface to make the pattern rise and have a 3D sense. After pasting, use various stitches to lock the edge.