In the realm of apparel printing, digital printing and screen printing are two primary techniques that cater to different needs and offer distinct advantages depending on the project requirements. Understanding their differences, strengths, and ideal applications can help apparel designers and manufacturers make informed decisions to achieve the desired aesthetic and quality.

Digital Printing: Precision and Versatility

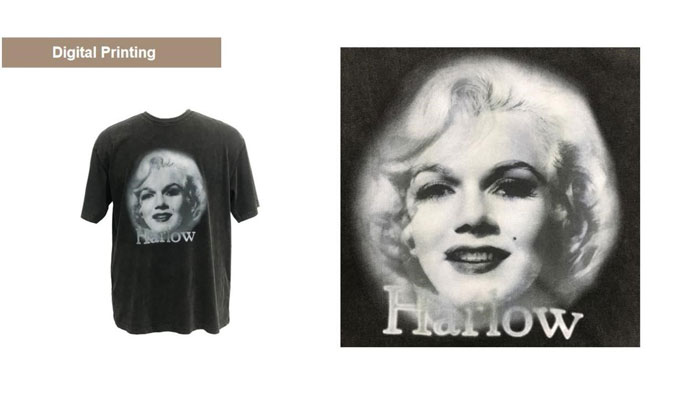

Digital printing in apparel involves using inkjet technology to transfer digital designs directly onto fabric. This method is known for its precision and ability to reproduce intricate details and vibrant colors from digital files. Unlike traditional methods, digital printing does not require screens or plates, allowing for greater flexibility and customization.

Key Characteristics of Digital Printing:

1. Color Accuracy and Detail:Digital printing excels in reproducing complex designs, gradients, and fine details with high color accuracy.This makes it ideal for apparel designs that feature photographic images, intricate patterns, or multicolored artwork.

2. Versatility in Design:Digital printing allows for customization and personalization of designs without additional setup costs. It supports variable data printing, making it suitable for producing unique pieces or small batches with different designs.

3. Soft Hand Feel: The ink used in digital printing penetrates the fabric fibers, resulting in a soft hand feel and minimal texture on the surface of the garment. This is especially desirable for apparel intended for everyday wear or garments worn close to the skin.

4. Quick Turnaround Times: Digital printing offers fast turnaround times since it does not require extensive setup or drying times. This agility makes it suitable for on-demand production and quick replenishment of inventory.

5. Environmental Considerations: Digital printing typically generates less waste compared to traditional methods like screen printing, as it does not involve excess ink or screens that need cleaning and disposal.

Applications of Digital Printing in Apparel:

- Fashion Apparel: Dresses, blouses, skirts, and other garments with intricate or photorealistic designs.

- Activewear and Sportswear: Customized jerseys, leggings, and performance apparel with vibrant graphics.

- Accessories: Scarves, ties, and bags featuring detailed patterns or custom designs.

- Limited Edition Collections: Capsule collections or collaborations requiring small production runs with unique designs.

Screen Printing: Durability and Vibrancy

Screen printing, also known as silk screening, is a traditional method where ink is pushed through a stencil (screen) onto the fabric. Each color in the design requires a separate screen, making it ideal for designs with fewer colors but larger quantities. Screen printing is valued for its durability, vibrant colors, and ability to create bold, opaque prints on various textiles.

Key Characteristics of Screen Printing:

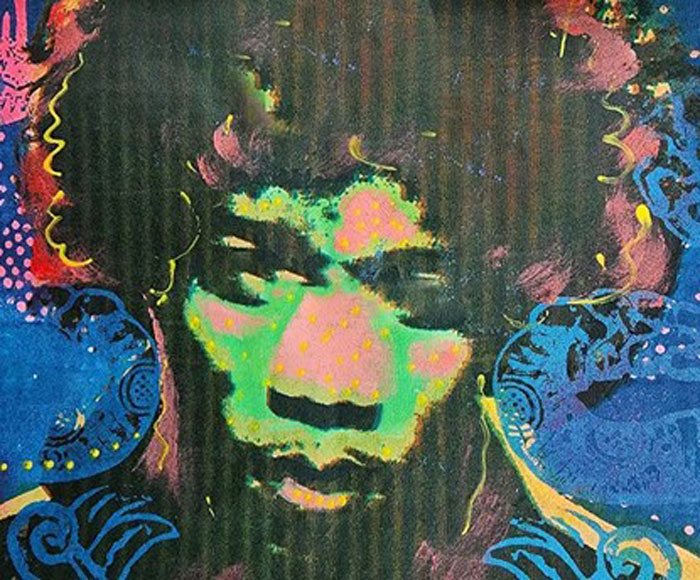

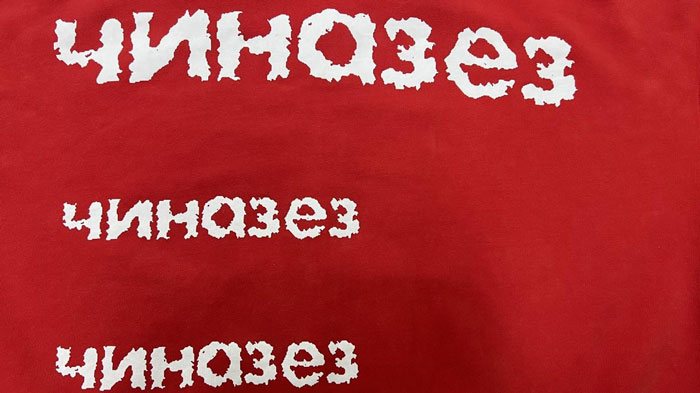

1. Vibrant Colors and Opacity: Screen printing produces vivid, opaque colors that stand out on both light and dark fabrics. The thick layers of ink create a bold, tactile texture that adds depth to the design.

2. Durability: The ink used in screen printing is highly durable and resistant to fading, washing, and wear. This makes it suitable for apparel intended for frequent use or exposure to harsh conditions.

3. Cost-Effective for Large Runs: While screen printing involves setup costs for creating screens, it becomes cost-effective for larger production volumes due to the efficiency of the printing process once the screens are prepared.

4. Specialty Inks and Effects: Screen printing allows for the use of specialty inks such as metallics, fluorescents, and textured inks that enhance design aesthetics and create unique effects not easily achieved with digital printing.

5. Versatility in Substrates: Screen printing can be applied to a wide range of textiles including cotton, polyester, blends, and even non-textile materials like plastics and metals, offering versatility in garment decoration.

Applications of Screen Printing in Apparel:

- T-shirts and Sweatshirts: Bold graphic tees, logo apparel, and promotional merchandise.

- Uniforms and Workwear: Customized uniforms for teams, events, or corporate branding.

- Fashion Accessories: Hats, tote bags, and patches requiring vibrant, durable prints.

- Bulk Orders: Apparel collections, merchandising lines, and promotional items with consistent designs over large quantities.

Choosing Between Digital Printing and Screen Printing for Apparel:

The choice between digital printing and screen printing depends on several factors including:

- Design Complexity: Digital printing is ideal for complex designs with multiple colors, gradients, and fine details, while screen printing is best for bold, simple designs with fewer colors.

- Quantity: Digital printing is cost-effective for small to medium runs, whereas screen printing becomes economical for larger production volumes.

- Fabric Type:Both methods are compatible with various fabrics, but screen printing may offer better results on thicker fabrics or materials requiring a textured finish.

- Turnaround Time: Digital printing offers quicker turnaround times for small batches or on-demand production, while screen printing is efficient for bulk orders once screens are set up.

In conclusion, digital printing and screen printing each offer unique benefits and are suited to different applications within the apparel industry. By considering factors such as design complexity, production volume, and desired print characteristics, apparel designers and manufacturers can determine the most appropriate printing method to achieve optimal results in terms of quality, durability, and visual impact for their garments.

Post time: Jul-11-2024